Engineering

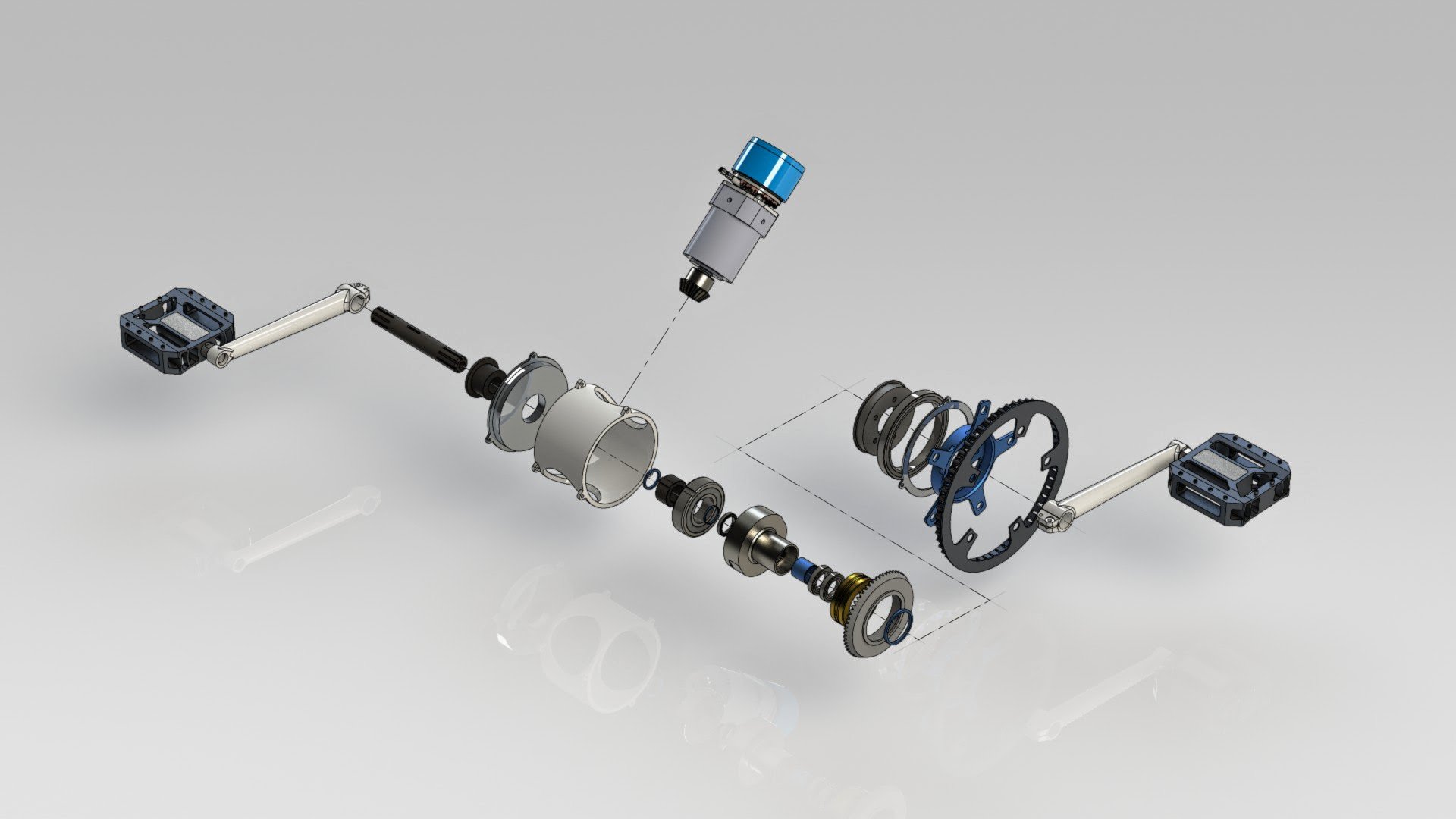

Engineering-led development of e-bike transmission systems — focused on ride feel, mechanical efficiency and clean integration.

FreeFlow Technology is an engineering company that originates, develops and validates e-bike transmission architectures.

Our work is driven by a simple objective: design drivetrain systems that ride and feel like a conventional bicycle, while meeting the packaging, service and efficiency demands of modern e-bikes.

We take a system-level approach — from rider input and motor assistance through to torque delivery at the wheel — and develop solutions intended either for future FreeFlow systems or for licensing and integration by OEM partners.

Engineering philosophy

We believe the quality of an e-bike drivetrain is defined less by peak power figures and more by how it behaves minute-to-minute on the road or trail. Drag, inertia, engagement behaviour, noise, service complexity and packaging all influence whether a system feels intuitive or intrusive.

Our engineering philosophy is therefore grounded in mechanical fundamentals and real-world use.

Core principles

System-level thinking: rider input, motor assistance and drivetrain behaviour treated as a single mechanical system

Mechanical efficiency: minimise parasitic losses and unnecessary rotating mass

Ride quality: predictable back-driving behaviour and natural pedalling feel

Integration: compact architectures that integrate cleanly into modern frames

Serviceability: designs intended to be maintained by standard bike mechanics using existing supply chains

What we engineer

FreeFlow’s engineering work centres on e-bike transmission and drivetrain architectures, from early-stage concepts through to prototype-validated systems.

This includes both internally originated system concepts and engineering programmes intended for licensing, transfer or partner-led industrialisation.

Primary focus areas

Transmission architecture and torque flow definition

Mechanical design of drivetrain subsystems and interfaces

Clutching and overrunning behaviour (engagement, back-driving, efficiency trade-offs)

Packaging and frame integration constraints

Electro-mechanical interfaces (sensing, actuation, routing and control boundaries)

Reliability, sealing and service considerations

Our work is structured to ensure that engineering decisions remain visible, testable and transferable.

From concept to prototype

We develop transmission systems iteratively, with a strong bias toward early physical validation.

Rather than pursuing broad optimisation too early, we focus on identifying the dominant mechanical questions and resolving them with targeted prototypes.

Typical development stages

System intent and constraints — ride feel targets, packaging envelope, service assumptions

Architecture selection — torque paths, component roles, key risk identification

Detailed mechanical design — CAD, tolerances, materials and manufacturable geometry

Prototype builds — focused on validating the highest-risk assumptions first

Measured iteration — refinement based on test data and teardown learning

Design consolidation — documentation suitable for further development or transfer

This approach supports both the development of future FreeFlow systems and the preparation of designs suitable for external partners.

Testing and validation

Drivetrain concepts only become meaningful once they are measured.

We use testing to understand not just whether a system works, but how and why it behaves as it does.

Validation is focused on behaviour that directly affects ride quality, durability and serviceability.

Areas of evaluation

Mechanical drag and loss sources across operating conditions

Back-driving and engagement behaviour during real riding scenarios

Noise, vibration and stiffness characteristics

Thermal behaviour and contamination control

Practical service operations and access

Testing methods are selected to be repeatable and informative, with results feeding directly back into design decisions.

Designing for ride feel, efficiency & integration

A central aim of our engineering work is to ensure that the presence of a motor does not dominate the riding experience.

This requires careful attention to mechanical details that are often invisible in specifications but immediately obvious to riders.

Design priorities

Reduce parasitic drag across bearings, seals and interfaces

Limit rotating mass where it most affects cadence and responsiveness

Maintain consistent engagement behaviour across loads and speeds

Achieve compact packaging that supports modern frame design

Enable realistic servicing without specialist tooling or procedures

These principles guide both our internal system development and any designs prepared for licensing or partner adoption.

System development & future platforms

FreeFlow’s engineering work includes the ongoing development of internally originated drivetrain system concepts, alongside earlier architectures within the wider portfolio.

Some systems are intended for licensing or sale, while others represent future FreeFlow product directions, to be progressed as programmes, partnerships and market conditions allow.

We deliberately avoid committing to fixed roadmaps in public.

Instead, we focus on ensuring that each system concept is technically coherent, mechanically validated and commercially realistic.

Working with partners

While FreeFlow originates its own systems, we also work with OEMs, suppliers and technical collaborators where alignment exists.

Partner engagement is typically structured around defined technical scopes, such as:

Architecture and packaging studies

Prototype-ready mechanical designs

Validation and test reporting

Service concept definition

Design transfer support

This model allows collaboration without overstating scale, while ensuring partners receive engineering outputs that integrate cleanly into established development processes.

What to expect from FreeFlow Engineering

We operate with a bias toward clarity, evidence and practicality.

You can expect

Clear definition of assumptions, constraints and trade-offs

Engineering decisions grounded in test data and physical behaviour

Designs that respect manufacturing and service realities

Discrete, well-scoped technical engagement

A long-term, system-led view of drivetrain development

If you are exploring future drivetrain architectures, integration strategies, or mechanically efficient transmission concepts, we are open to a technical discussion.

Optional CTAs