Technology

FreeFlow Technology develops transmission architectures for electric bicycles. Our work focuses on the system-level integration of gearing, control, sensing and rider interaction into solutions that are manufacturable, serviceable and compatible with OEM development processes.

This page provides a high-level technical overview of the problem space we address, our architectural approach, and our granted patent portfolio. The information presented here is intentionally high-level and does not describe specific implementations or claim-level detail.

The Technical Problem

Electric bicycles impose drivetrain requirements that differ materially from those of conventional bicycles. Higher and more variable torque, continuous motor assistance, frequent load changes and compact frame packaging introduce challenges that cannot be addressed reliably through isolated component optimisation.

At the same time, many e-bike use cases require the drivetrain to operate efficiently in partially assisted or unassisted riding modes, where mechanical losses, parasitic drag and back-driving behaviour directly affect rider feel and energy transfer. As a result, transmission architectures must account for both electrically assisted and purely mechanical operating conditions.

Key technical considerations therefore include drivetrain load paths through the crank area, shift behaviour under load, management of mechanical losses, durability and contamination control, system efficiency across operating modes, control-system integration, and predictable assembly and service procedures. Addressing these factors requires a coordinated transmission architecture rather than independent mechanical or electronic subsystems.

A System-level Transmission Approach

Our transmission architectures are developed with the objective of preserving natural mechanical behaviour across both assisted and unassisted riding conditions. In practical terms, this means designing the transmission so that rider input remains the primary reference for drivetrain behaviour, with motor assistance integrated as a supplementary input rather than a dominant one.

From a system perspective, the transmission is intended to manage the interaction between human power and motor power in a continuous and predictable manner. This includes consideration of back-driving behaviour, mechanical losses, torque superposition and shift execution, such that the drivetrain behaves consistently whether assistance is present, reduced or absent.

At an architectural level, this approach addresses how torque is introduced and removed, how load is managed through shift events, how the transmission interfaces with the bicycle frame and electrical system, and how the overall assembly can be manufactured, validated and serviced at scale.

Electronic Transmission Systems (ETS)

Within this site, Electronic Transmission System (ETS) refers to transmission architectures developed for electrically assisted bicycles, in which mechanical gearing is integrated with electronic sensing, control and actuation.

ETS architectures are designed to manage the interaction between rider input and motor assistance as a single system, with defined interfaces for integration into e-bike platforms. The scope covers system layout, power interaction and integration considerations, rather than specific component implementations.

Mechanical Transmission Systems (MTS)

Within this site, Mechanical Transmission System (MTS) refers to transmission architectures developed primarily for non-assisted bicycles, where drivetrain behaviour is governed by mechanical interaction alone.

MTS architectures focus on managing torque transfer, inertia and drivetrain continuity through mechanical means. This includes configurations intended to decouple rider input from downstream drivetrain inertia under certain conditions, while retaining the dynamic characteristics associated with fixed or direct-drive systems.

Engineering principles

Our transmission architectures are developed around a consistent set of engineering principles:

Mechanical continuity – preserving consistent drivetrain behaviour across assisted and unassisted operation

Compact integration – compatibility with mainstream bicycle frames and established assembly processes

System robustness – predictable behaviour under high torque, transient loads and environmental exposure

Managed shifting behaviour – defined shift execution and load management across operating conditions

OEM integration – clear interfaces to frame structures, electrical systems, controls and service procedures

Manufacturability and serviceability – practical considerations addressed from early design stages

Patent portfolio (high-level overview)

FreeFlow Technology maintains a portfolio of granted patents covering aspects of electronic and mechanical transmission architectures for bicycles. The summaries below are provided for technical orientation only and do not describe claim-level detail.

Patent portfolio (high-level overview)

FreeFlow Technology maintains a portfolio of granted patents covering aspects of electronic and mechanical transmission architectures for bicycles. The summaries below are provided for technical orientation only and do not describe claim-level detail.

-

Scope (high-level):

Electronic Transmission System architecture building on earlier ETS concepts, addressing system-level interaction between mechanical gearing and electronic control within an e-bike drivetrain.

Focus area:

System interaction and control architecture associated with electronically integrated bicycle transmissions.

Grant status:

Granted in Taiwan.

Public records (example):

-

Scope (high-level):

Later-generation Electronic Transmission System architecture developed for e-bike applications, addressing transmission integration, system refinement, Q-Factor reduction of motor, gearbox and pedals and scalability within electrically assisted drivetrains.

Focus area:

System evolution, integration and architectural refinement of electronically integrated transmission systems.

Grant status:

Granted in multiple jurisdictions including Europe, United Kingdom, USA, China, Japan, Australia and others.

Public records (example):

-

Scope (high-level):

Mechanical Transmission System architecture developed for non-assisted bicycles, defining drivetrain configurations in which rotational inertia and downstream drivetrain dynamics can be utilised while permitting controlled decoupling between rider input and the driven transmission elements.

Focus area:

Management of mechanical torque transfer, drivetrain inertia and continuity, including architectures that allow the crank mechanism to be disengaged from the driven chainring under defined operating conditions.

Grant status:

Granted in the United Kingdom, USA and Taiwan.

Public records (example):

-

(including original and related divisional filings)

Scope (high-level):

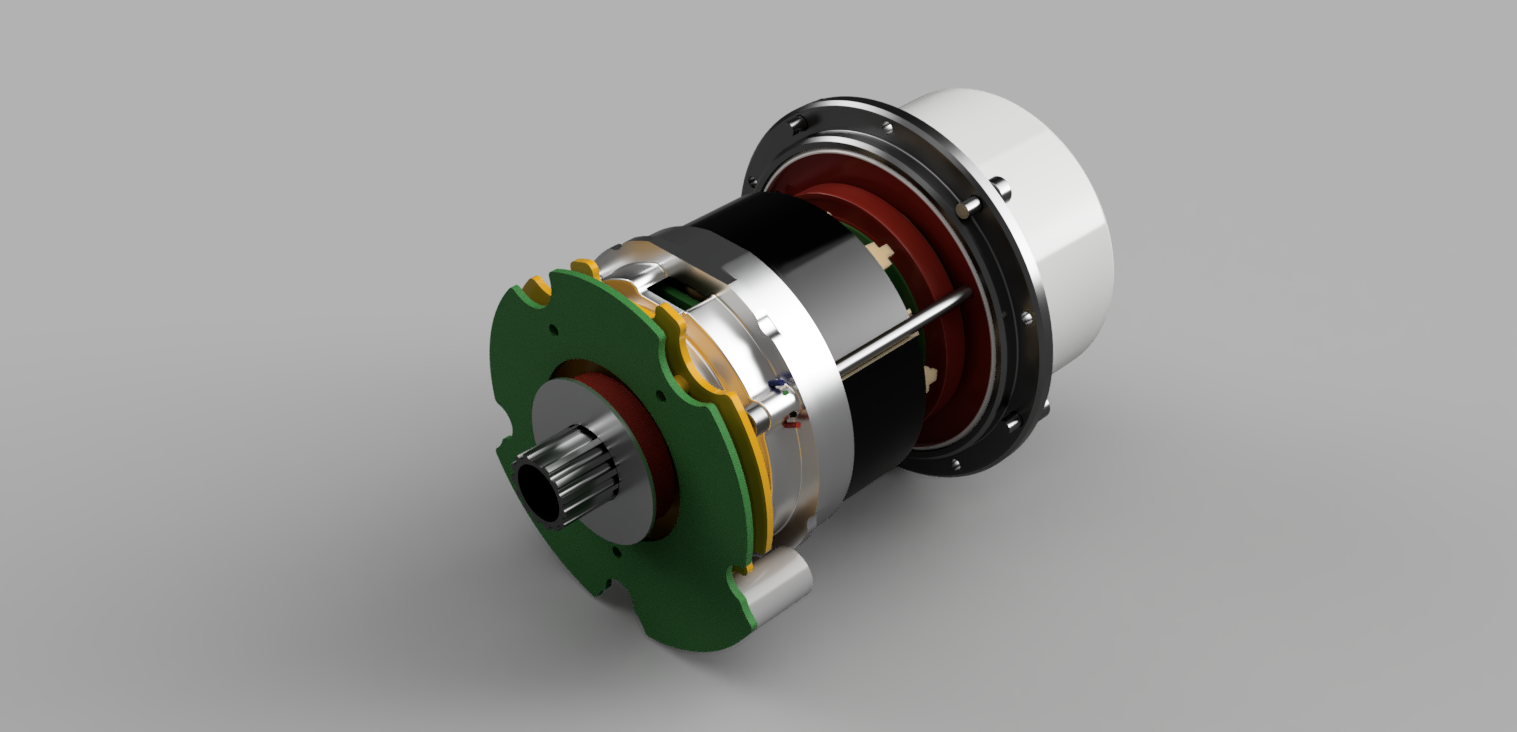

Foundational transmission architecture developed by FreeFlow Technology for electronically integrated e-bike drivetrains. The architecture defines how rider input and motor assistance are introduced into the drivetrain as coordinated, system-level torque paths, with the objective of preserving efficient power transfer, predictable back-driving behaviour and compact drivetrain geometry.

Focus area:

System-level management of rider and motor torque interaction, drivetrain continuity, and integration within the crank and chainring region of an e-bike platform.

Grant status:

Granted in multiple jurisdictions including Europe, United Kingdom, USA, China, Japan, Taiwan and others.

Public records (examples):

(including original and related divisional filings)

Scope (high-level):

Foundational transmission architecture developed by FreeFlow Technology for electronically integrated e-bike drivetrains. The architecture defines how rider input and motor assistance are introduced into the drivetrain as coordinated, system-level torque paths, with the objective of preserving efficient power transfer, predictable back-driving behaviour and compact drivetrain geometry.

Focus area:

System-level management of rider and motor torque interaction, drivetrain continuity, and integration within the crank and chainring region of an e-bike platform.

Grant status:

Granted in multiple jurisdictions including Europe, United Kingdom, USA, China, Japan and others.

Public records (examples):

European patents are validated and maintained at national level. Full jurisdictional details are available via public patent records or on request.

-

Scope (high-level):

Mechanical packaging architecture addressing the mounting, housing and structural integration of transmission components within a bicycle frame.

Focus area:

Transmission housing, structural integration and packaging considerations.

Grant status:

Granted in the United Kingdom and other jurisdictions.

Public records (example):